Proven tips for using Core Drilling Equipment safely and efficiently

Everything About Core Boring Devices: A Comprehensive Overview to Its Types and Uses

Core boring devices plays an essential role in discovering subsurface products throughout different markets. Comprehending the different kinds of core bits and their specific applications is vital for efficient use. This tools not only help in collecting crucial geological data yet also impacts decision-making in markets like mining and building and construction. To totally appreciate the importance of core boring, one should take into consideration the diverse tools offered and their correct upkeep practices.

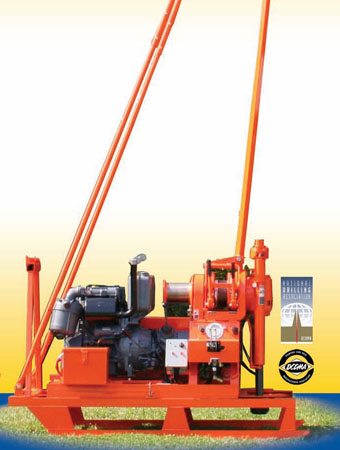

Recognizing Core Drilling Equipment: A Summary

Core boring equipment plays a vital function in geotechnical exploration and mineral removal. This specialized equipment is developed to acquire round examples of subsurface products, permitting detailed analysis of geological developments. The procedure entails drilling into the ground to draw out a core sample, which can provide useful information regarding dirt composition, rock layers, and mineral down payments.

Core boring is fundamental for site evaluation, enabling engineers and rock hounds to make enlightened decisions relating to building jobs and resource removal. The tools is normally powered by innovative machinery that guarantees precision and performance, lessening environmental influence. Different aspects, such as drill little bit style and operational strategies, affect the performance of core boring. Understanding the capabilities and restrictions of core exploration tools is essential for experts in the field, as it directly influences the high quality and honesty of the gathered samples, eventually assisting calculated preparation and source administration.

Kinds Of Core Drilling Equipment and Their Functions

Rotating drilling rigs give the needed power to advance the little bit right into the ground, while core barrels are used to retrieve the core samples. These barrels can be found in different styles, such as wireline or traditional, each offering distinct advantages in sample recovery. Furthermore, casing systems are used to support the borehole and protect against collapse. Together, these devices develop a natural system that permits detailed geological exploration and evaluation.

Applications of Core Drilling in Various Industries

Many industries depend on core boring for essential applications, ranging from mining and ecological researches to construction and geotechnical engineering. Core Drilling Equipment. In mining, core boring is essential for exploration, allowing firms to assess the mineral content of rock developments and make educated choices concerning source extraction. Environmental studies utilize core sampling to analyze soil and groundwater, helping to determine contamination and educate removal initiatives

In building and construction, core boring is made use of to develop specific holes in various materials, helping with the setup of utilities and architectural assistances. Geotechnical engineering uses core drilling to collect subsurface information, vital for reviewing site conditions and making certain the safety and security of structures. In addition, the oil and gas sector depends on core exploration to remove geological samples, which are vital for reservoir evaluation. Overall, core boring functions as an essential tool throughout these industries, giving valuable understandings and enhancing operational performance.

Elements to Take Into Consideration When Selecting Core Drilling Tools

When selecting core drilling tools, it is important to think about numerous vital elements that can substantially impact the performance and effectiveness of boring procedures. Initially, the sort of product being pierced is essential, as tougher products might require specific little bits and even more powerful drill rigs. Next, the size and depth of the core examples required should dictate the option of equipment, guaranteeing that it fits the specific project requirements.

Furthermore, the boring approach-- whether wireline Recommended Reading or rotary-- can influence performance and price. The mobility and weight of the equipment are likewise vital, specifically for projects in remote places. Budget restrictions should be considered, balancing first expenses with long-term durability and maintenance needs. Assessing maker track record and client comments can supply understandings right into equipment dependability and support services. By evaluating these aspects, drivers can select one of the most appropriate core drilling devices for their projects.

Maintenance and Best Practices for Core Drilling Tools

Correct upkeep and adherence to finest techniques are vital for ensuring the long life and performance of core drilling devices. Normal evaluation is essential; drivers must check for indications of wear, damages, or misalignment prior to each usage. Keeping the devices tidy is equally essential, as particles can hinder performance and bring about premature wear. Oiling moving components according to the manufacturer's requirements assists decrease friction and prolongs device life.

It is suggested to comply with the recommended operating speeds and feed prices, as exceeding these restrictions can cause getting too hot and device failure. Operators needs to additionally ascertain that the drill little bit appropriates for the product being drilled, as making use of an incompatible little bit can result in inefficient boring and increased wear. Ultimately, proper storage in a dry, protected area avoids deterioration and damage, more enhancing the resilience of core boring devices.

Frequently Asked Questions

What Security Equipment Is Recommended When Utilizing Core Exploration Tools?

When utilizing core boring devices, it is suggested that drivers wear construction hats, security goggles, gloves, ear security, and steel-toed boots. These products improve personal security and aid protect against injuries throughout exploration operations.

Exactly how Do I Correctly Throw Away Core Examples?

Core samples need to be dealt with according to neighborhood laws, typically entailing sealing in proper containers and delivering to assigned waste centers (Core Drilling Equipment). Ecological factors to consider have to from this source be prioritized to stop contamination and assurance compliance with safety criteria

Can Core Exploration Be Performed In Extreme Weather Issues?

What Is the Typical Lifespan of Core Boring Tools?

Are There Eco-Friendly Alternatives to Typical Core Drilling Methods?

Yes, green choices to standard core boring approaches exist. Methods such as geothermal drilling and using biodegradable lubricants minimize environmental influence, advertising lasting techniques while preserving efficiency in core tasting and extraction procedures.

Core exploration equipment plays an essential function in exploring subsurface materials across different industries. Core drilling equipment plays a vital role in geotechnical exploration and mineral removal. Rotary drilling rigs provide the necessary special info power to progress the bit into the ground, while core barrels are utilized to recover the core samples. When choosing core boring tools, it is crucial to take right into account a number of crucial elements that can significantly influence the performance and efficiency of boring operations. When making use of core exploration devices, it is advised that drivers wear difficult hats, security goggles, handwear covers, ear security, and steel-toed boots.